Smart Textiles, Wearable Electronics and Integrated Systems

Interactive Wear develops and produces electronic systems designed for textile integration and wearable systems enabling customers to digitize, interconnect and innovate their products. Our functional focus covers heating, light, sense and feedback solutions. We utilize technologies such as flexible conductive textiles, connectivity components and modular electronics platforms. Our distributed software architecture includes real-time embedded systems, application software and mobile applications.

Our systems are part of more than 100 products in market segments such as sport, fashion, workwear, rehabilitation, as well as interior design.

Smart Textiles

We use conductive textiles to develop and produce lightweight, flexible but robust systems. We collaborate with leading research institutes and specialists for embroidery, weaving and trims to provide components for apparel and interior designers.

Our smart textile components are the proven backbone for integration of wearable electronics into our customers' products.

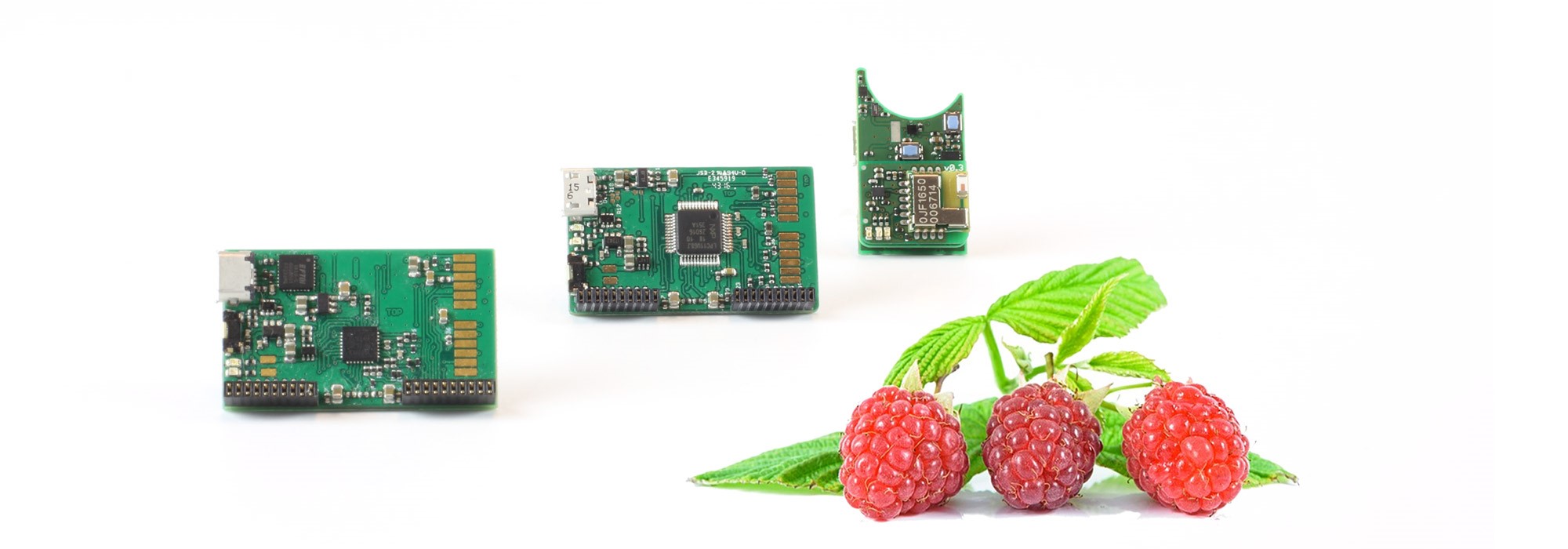

Wearable Electronics

We focus on electronics integrated into flexible environments, especially garments and other textile products. One of the main differences compared to mobile devices is the usage of distributed architectures, flexible materials and special textile compliant integration methods and techniques.

Our wearable electronic components functionalize our customers' products and turn them into smart devices.

Integrated Systems

We offer components and techniques to merge electronics with textiles, resulting in smart systems and products. We provide new concepts of multimodal user interaction, comprising textile products as smart interface, the integrated electronics for data acquisition and control, application software for data analysis and mobile applications for complex user interaction.

Our integrated systems transform our customers' products into objects of the internet of things, controlled by their users.

What we do

Product Development

From Idea to Product

We develop customer specific wearable products from idea to manufacturing, delivering systems for demonstrators, prototypes, pre-series and volume production.

Customers take advantage from our existing platforms, enabling fast time to market combined with reduced development risks.

CONSULTING & ENGINEERING

Leverage Experience

We provide a fast access to the basics and principles of wearable electronics.

We help to evaluate product concepts or developed components, leveraging our development know-how and industrialization experience from more than 130 projects as well as our R&D partner network for electronics and smart textiles.

COMPONENTS & SYSTEMS

From Material to Platforms

We offer components and systems to build wearable products and smart textile solutions. Our portfolio ranges from textile cables for interconnections, textile heating pads, LED solutions to power banks suitable for usage in wearables.

Sample systems are available for sensing, heating and light solutions.

Project Examples

OPED Orthelligent

A motion sensor unit mounted on the lower leg, combined with a training app, enables patient and therapist to optimize and speed up the rehabilitation process.

Development system: MicroHub Pro

Heated mattress for patient transport

A powerful mobile heating electronics combined with sensor controlled heating pads is the core technology for AKMedTec's innovative product.

Development system: H60

Sensor fusion & real-time feedback

Feraru Dynamics has developed a system to provide real-time alerts based on vibration perceived by user’s hand, preventing overexposure and driving the formation of robust control measures.

Development system: MicroHub One

08

March

2023

Interactive Wear wins the QRDI's qatar open innovation award for Smart PPE

Interactive Wear wins the QRDI's Qatar Open Innovation Award for "Smart Personal Protective Equipmen (PPE) for Worker's Health, Safety and Security"

The goal of the Work Trial is to generate data with and without active cooling solutions. These data will be enriched by data from occupational health reports and analysed with neural networks. The expected outcome are validated algorithms for an embedded Thermal Monitoring System that could be used for an alert system as well as for health documentation and objective insight about the health and performance effect of active cooling solutions and proposals for the most effective and efficient active cooling components. The thermal monitoring system will include climate and temperature sensors, enhanced with other sensors (e.g., activity sensor, respiration sensor, smart watch integration).

23

february

2023

Ergonomic assistance systems for grid control centers in critical infrastructures

Project Kickoff BEAUTIFUL, Aachen, 23./24.02.2023

The increasing technological and systemic complexity of energy systems and the increased risk of cyberattacks lead to a significant increase in relevant process information that needs to be considered by the control center operators. The BMBF-funded BEAUTIFUL project aims to optimise the working conditions of the operators in critical infrastructures by developing innovative assistance systems to support fast and safe decisions in complex situations.

Interactive Wear will implement distributed wearable sensors and sensor fusion algorithms to measure physiological data of the operators to determine the stress level and mental fatigue.

20

january

2022

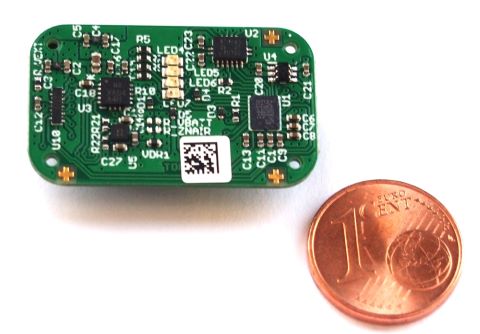

Interactive Wear adds NFMI communication to its technology portfolio

Adding NFMI (near field magnetic induction) technology enables Interactive Wear to support customers in new areas of BSN (Body Sensor Networks) and IoT applications, where conventional RF technologies have their limitations.

In the recently completed BIONIC project for posture and fatigue analysis in industrial and construction work environment, Interactive Wear realized a near field magnetic induction (NFMI) communication node to connect a head-worn sensor with a textile wired BSN. NFMI was chosen to provide stable, private and low energy communication in industrial and construction environments. The systems were successfully tested at Rolls Royce Power Systems in Friedrichshafen, Germany.

NFMI is well suited for low power wireless communication where Bluetooth has its limitations, especially for communication through the body, in shoe-soles or under water.

The NFMI technology has several benefits compared to conventional RF technology.

- It does not interfere with Bluetooth and Wi-Fi

- It is private because of the very limited range of transmission

- It works under water, as water does not absorb the magnetic field

- It is power efficient as NFMI devices last up to five times longer than comparable Bluetooth devices

- It is multi-point and real-time capable, designed to connect many devices

Interactive Wear’s BSN is a modular wired/wireless multi-sensor system that enables a wide range of applications through sensor fusion using motion analysis, climate and vital parameters. The system can integrate sensor data from smart phones and smart watches, as well as customized third-party sensor data. New insights can be generated through neural network capabilities, e.g., detecting new patterns and events for monitoring applications. Communication via textile cable and wireless via Bluetooth LE has been extended by an additional technology NFMI.

Customers can be supported in developing NFMI applications via prototyping workshops, feasibility studies, and custom specific development projects.